Innovations and Future Prospects in Medical Injection Molding

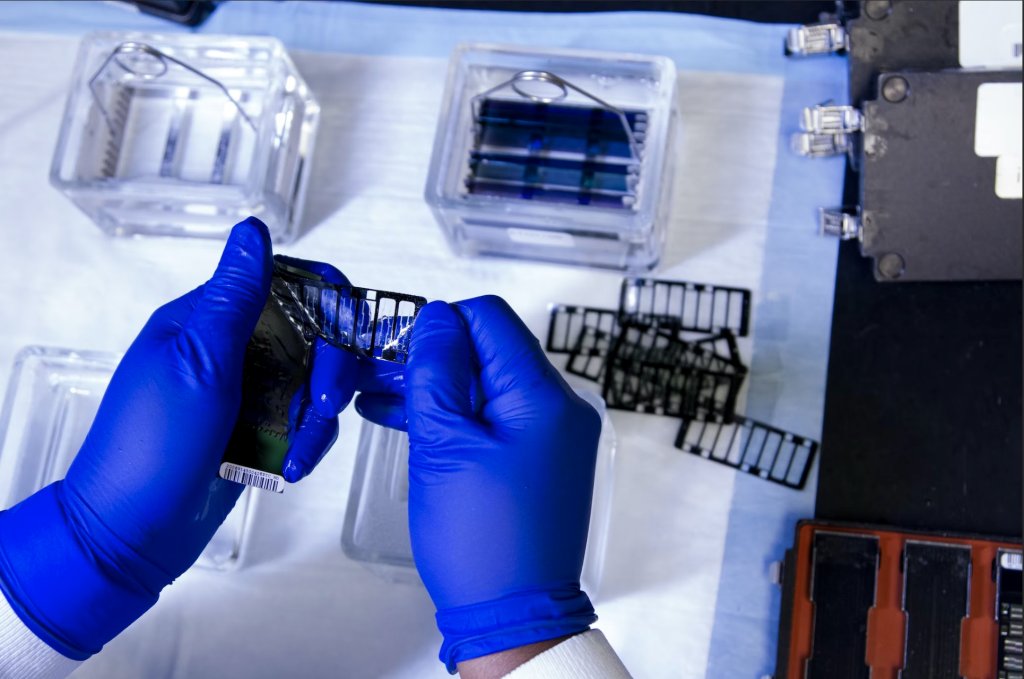

The field of medical injection molding is constantly evolving, driven by innovative technologies and a continuous quest for improved patient care. In this article, we explore the latest advancements and future prospects in medical injection molding supplies. With a focus on medical micro molding, we delve into the cutting-edge techniques, materials, and trends that are shaping the future of this vital industry.

Advancements in Medical Micro Molding

Medical micro molding represents a significant leap forward in precision manufacturing for the healthcare sector. This specialized form of injection molding enables the production of intricate, ultra-small components that are crucial in the development of cutting-edge medical devices. With micron-level tolerances and intricate geometries, medical micro molding allows for the creation of microfluidic devices, micro connectors, surgical tools, and drug delivery systems with unmatched precision and performance.

Materials Revolutionizing Medical Injection Molding Supplies

The selection of suitable materials is a critical aspect of medical injection molding. Recent years have witnessed a revolution in the range and performance of materials available for medical device manufacturing. Biocompatible polymers, such as thermoplastic elastomers, bioresorbable materials, and liquid silicone rubbers, have gained prominence due to their enhanced biocompatibility, sterilizability, and mechanical properties. These materials enable the production of safe, reliable, and patient-friendly medical components.

Automation and Robotics in Medical Injection Molding

Automation and robotics are transforming the medical injection molding landscape, offering increased precision, efficiency, and cost-effectiveness. Robotic systems integrated with injection molding machinery can perform tasks such as insert placement, part removal, and quality inspection with unmatched speed and accuracy. Automation streamlines production processes, reduces labor requirements, and minimizes human error, enhancing the overall quality of medical components.

Enhanced Quality Control and Process Validation

Quality control and process validation are critical in the medical injection molding industry to ensure the safety and reliability of medical devices. Advanced technologies, such as real-time process monitoring, automated inspection, and statistical process control, have significantly improved quality control procedures. These innovations provide real-time data on manufacturing processes, enabling rapid detection of any deviations and ensuring adherence to specifications and regulatory requirements.

Industry Trends and Future Outlook

The future of medical injection molding is bright with several emerging trends on the horizon. One such trend is the increasing use of additive manufacturing (3D printing) in the production of medical components. 3D printing allows for complex geometries, customization, and rapid prototyping, revolutionizing the design and manufacturing process. Another trend is the growing adoption of bioresorbable materials, facilitating the development of implantable medical devices that safely degrade over time, eliminating the need for surgical removal.

Conclusion

The field of medical injection molding continues to push boundaries, driven by technological advancements and a focus on patient-centric care. Innovations such as medical micro molding, advanced materials, automation, and enhanced quality control are revolutionizing the production of medical components. As the industry moves forward, the integration of additive manufacturing and the development of bioresorbable materials promise exciting possibilities. With these advancements, medical injection molding supplies are poised to play a crucial role in delivering safer, more efficient, and patient-friendly medical devices, ultimately improving healthcare outcomes for patients worldwide.